Automated Media Dispensing System

AMD110

For laboratories involved in culture media preparation, sterile dispensing is essential for successful downstream applications and to meet quality requirements. Furthermore, as a growing need for cost saving and performance improvements exists, a reliable work flow is necessary. These requirements create a strong demand for medium dispensing system that allows reliable walk-way operation and at the same time fulfills quality requirements. AMD series and HMD series are developed to meet these needs.

Solve existing problem

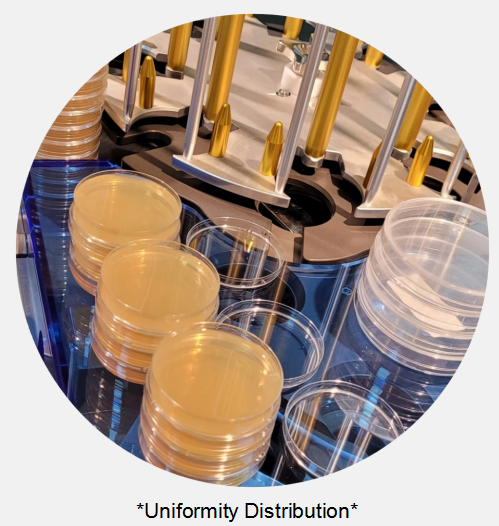

1. Dispensing media by person —Nonuniformity dose, heavy working intensity, poor efficiency and easy contamination.

2. Purchase prepared media —High cost, short shelf life(max. not more than 6 months), frequency purchase, high storage requirement for transportation(2- 25 degree protect from light), especially, required for cold-chain transportation.

3. Media dispensing system —Automated dispensing, high efficiency, eliminating source of contamination, solve the limited condition problem of big batch storage and transportation.

Automated AMD110

Parameter and Feature

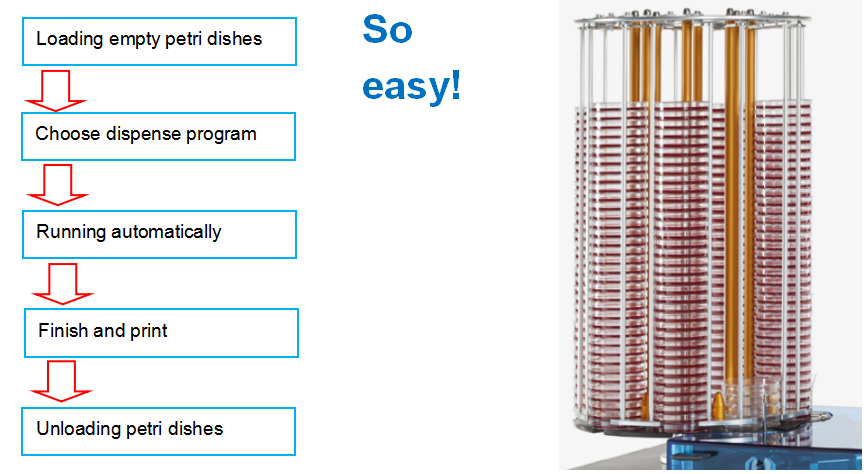

1. Composed by three parts: Main control system, rotor system and carrousel.

2. New 7inch big touch screen and intelligent operation system, easy handling.

3. Special feed support for empty dishes, avoiding jam during down into the feed position.

4. The material of rotor and carrousel are adopts hard aluminum alloy, easy to disassemble.

5. Two types of carrousel for choice: 110 (accept customized).

6. The dispensing area is protected by UV rays, reduce the risk of containment.

7. Dispensing volume from 1-1000ml, its precision is less than 1%. Dispensing 110 petri dishes in less than 12 minutes.

8. Fast calibrate dispensing volume, can set parameter as need for suitable dispensing program, and different dispensing programs can be stored.

9. Manual dispense function can set dispense volume, dispense times and dispense time interval.

10. Adopts curved spring plate in the carrousel which is easy for unloading dishes.

11. Having fault alarm and self-check function, fast to find fault and repair.

12. Can connect with ink printer for petri dish data tracing.

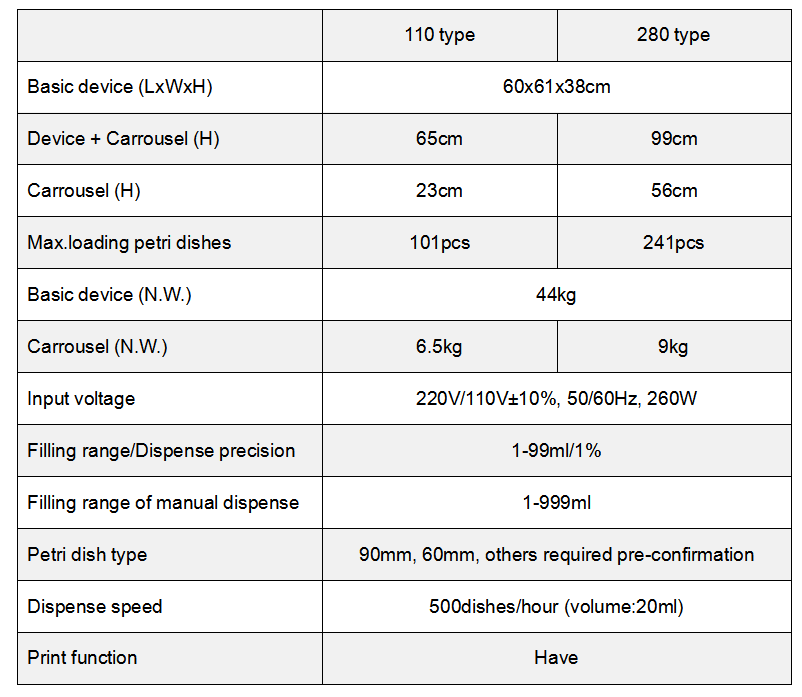

Technical parameter